Paying attention to head size helps with determining integrity, protrusion, and aesthetic value. The heads of dome rivets reside above the material, and large flange rivets take the concept further by covering more area and providing extra fastening capabilities. Head Sizeįlat head pop rivets are flush with the material being fastened. This ensures shear and tensile strength and improves the longevity of the setting tool. When considering grip range, best practice dictates a rivet that isn’t directly on the minimum or maximum points, but rather, comfortably in-between. If, for example, you are attaching two quarter-inch pieces of metal together, you will require a pop rivet with a minimum grip of at least a half-inch.

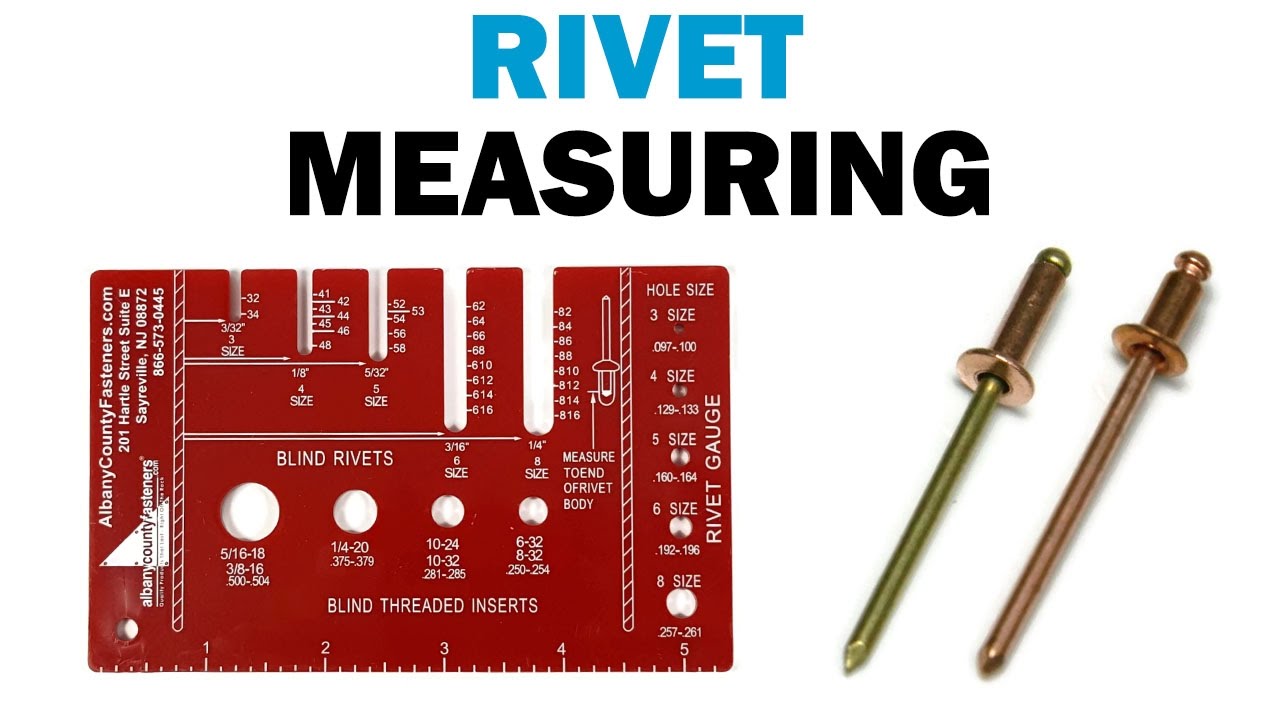

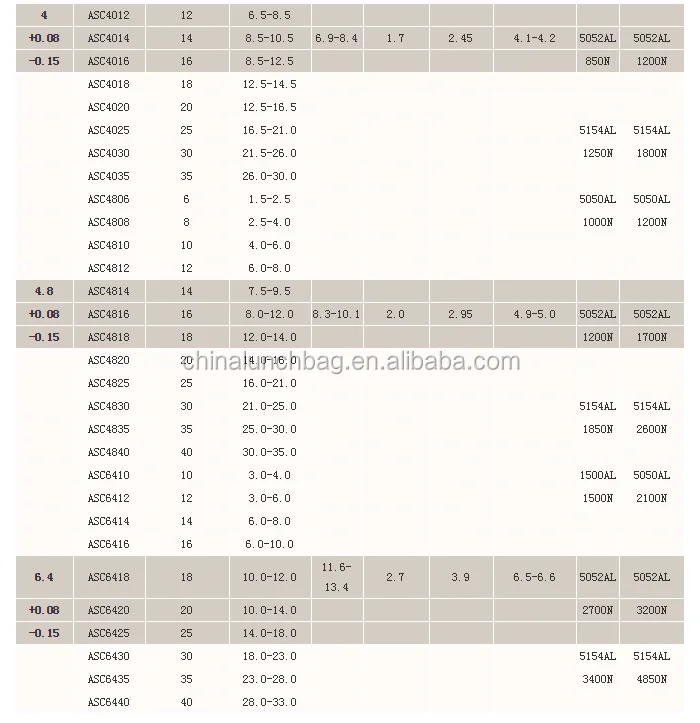

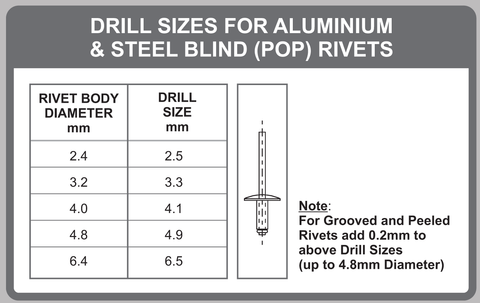

Grip range is the thickness of material that a rivet can effectively fasten. It differs from grip range (which will be explained next), but is an important measurement when considering clearance on the blind side of the material being fastened-a rivet that’s too long may not properly fit or could negatively impact whatever resides behind the hole. Body Lengthīody length is the total length of the pop rivet (not including the head). Carefully measure hole sizes, and never force a pop rivet into anyplace that doesn’t match its diameter. If a rivet is too wide for its hole, it will be harder to place and result in a poor fit. A rivet that’s too narrow for its hole can leave a gap, which can increase shear stress or cause installation problems also, the blind head could expand in the space between the two workpieces. Here are some factors to consider when choosing a size for your rivets: Diameter and Hole Sizeĭiameter is a critical consideration when choosing the proper pop rivet for your application. That said, correctly sizing pop rivets is crucial to the success of the application. Also known as blind rivets (and if they are coming from the Stanley brand, POP® rivets), pop rivets offer versatility, strength, and ease of use. More than 80 years later, pop rivets are standard in a tremendous range of applications, projects, and industries. On an all aluminum blind rivet, both the hat and mandrel of the rivet have all of these qualities making these fasteners a versatile, durable, lightweight and inexpensive solution.In 1934, an aircraft manufacturer approached the George Tucker Eyelet Company with a challenge: Could it design a rivet that could be set from one side, particularly if there was no access to the other side of the material? The company was up to the challenge and developed the first pop rivet-so named because of the popping sound made during installation. We recommend only using aluminum with aluminum to help prevent galvanic corrosion.

It can also be used for many electrical applications due to its high levels of conductivity. Aluminum is not magnetic, accepts paint well, and is non-staining. Aluminum as an alloy forms its own protective coating making it resistant to atmospheric corrosion and is generally less expensive than stainless steel fasteners of the same type. Aluminum Rivets in this selection feature an all aluminum design meaning that both the hat and mandrel of the rivet are made of aluminum unless designated otherwise.Īluminum rivets are used for a variety of reasons besides weight as well.

Pop rivet sizes install#

Rivets are used because they are a quick and easy way to join two pieces of material together, and do not require threading making them ideal for use with thin metals and other thin application surfaces.Blind rivets require access to the installation surface from only one side, making them easy to install with the use of a rivet gun or hand riveter.Īluminum blind rivets are commonly used in the automotive, aerospace, boating and metal fabrication industries due to the high strength-to-weight ratio of the metal. Also known as blind rivets or pull rivets, this type of rivet is used due to its efficiency and ease of use.

0 kommentar(er)

0 kommentar(er)